The machine did 1 full test and then died at about 1/3 of the second test. The first test result is 32,066 iterations, supporting the result from the Test Machine #1 which ended with 37,112 iterations. So the average is at 34,589 for the moment.

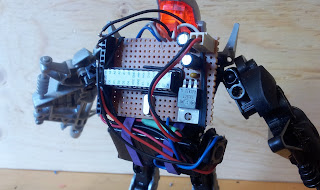

So, why is the machine #2 dead? It didn't died as much as it was slaying DC motors and it all came down to a bad design. One of my goal was to build the machine with only (as much as possible) the Makeblock parts that TLBRC* sent me. It turns out that I found my nemesis in the motors that where included in the two kits. DC motors.

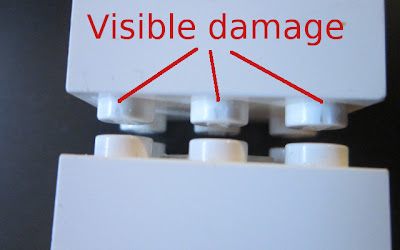

For something like this build, every molecules in my body was screaming stepper-motors or, at least, servos. But NoooooOOOoooo, it had to be DC motors, so I looked around for ideas to use them in the same way I would use stepper-motors. The result was to build physical barriers to stop the motor in known positions. I knew this would not be good on the motor's gears so I monitored the current going into the DC motors and “tried” to stop them before they were straining. At this point in the story, all the engineers are rolling on the floor laughing. Well, 3 dead motors later, I've learned my lesson: Engineers are cruel and, most importantly, DC motors and made to run freely like wild mustangs in prairies.

The following video was made after the machine killed its first motor. At that point I thought I could fix it:

Here is my sad video when I decided to stop the machine for good:

What now? Thanks to Galaxy Quest, my motto is “Never give up, never surrender” and so I have 2 plans:

- Build a simple machine using stepper-motors.

- Find a DC motor friendly design and try that too.

But, in order to keep my sanity, I will take a short break from this and work on other projects.

R.I.P. LEGO Test Machine #2. At least you did 1 full test.

*Again a big thanks to The Little British Robot Company for the 2 Makeblock kits that were used for building this project. I will reuse those parts on a project pretty soon

Edit:

This story was covered on: